Glittering Cargo

The last piece of the world’s largest telescope takes shape at UArizona.

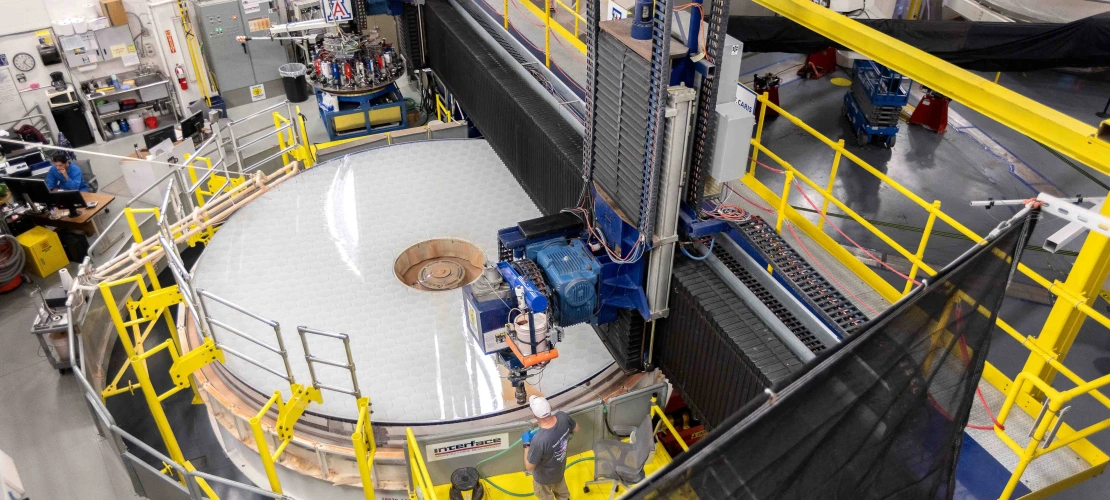

Part of the final segment of the primary mirror required to complete the Giant Magellan Telescope

Photos: Chris Richards

To make one of the world’s largest mirrors requires a lot of glass — 80 crates of it, to be exact, each containing 25 cases. And delivering that glass means safeguarding it on double springs and distributing it among the holds of four semitrucks.

Last September, this fleet of trucks parked outside Arizona Stadium, whose basement houses the University of Arizona’s Richard F. Caris Mirror Laboratory, and unloaded its glittering cargo. Forklifts trundled across polished cement floors, carrying 20 tons of gleaming borosilicate glass cubes, dense and clear as cut ice. Careful hands sorted the glass, discarding impurities, and loaded it into a rotating furnace 40 feet across.

Beginning in October, technicians heated the glass to 2,129 degrees Fahrenheit — the temperature of flowing lava — and set the furnace to spin. It was the start of a four-year process of meticulously engineered melting, casting and polishing that will result in a lightweight mirror nearly three stories high when stood on end.

The mirror will be shipped 5,000 miles to the Las Campanas Observatory in Chile’s high desert to become the final segment of the primary mirror required to complete the Giant Magellan Telescope — the world’s largest telescope.

At 50 million times the power of the human eye and 10 times the resolution of NASA’s Hubble Space Telescope, the GMT will give astronomers glimpses of the earliest, most distant stars and galaxies in the ongoing quest to understand the origins of life in the universe.